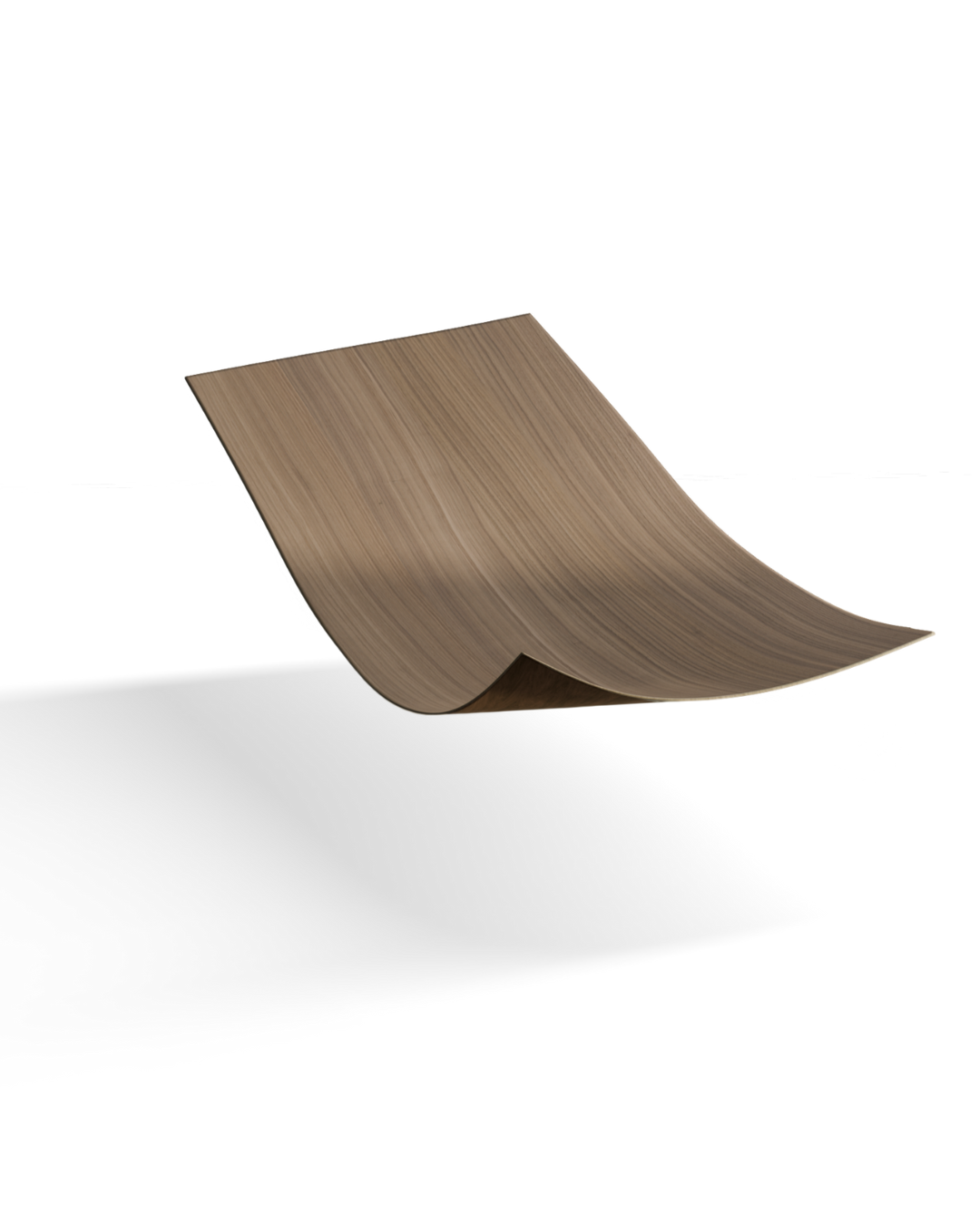

The perfect edge finish

The edge bandings are specially developed for finishing the panels of the Nuxe collection. The veneer edge bandings are already pre-sanded, but they still need to be finished with stain, oil or varnish. If necessary, an excess of glue between the panel and the edge banding has to be sanded straight away.

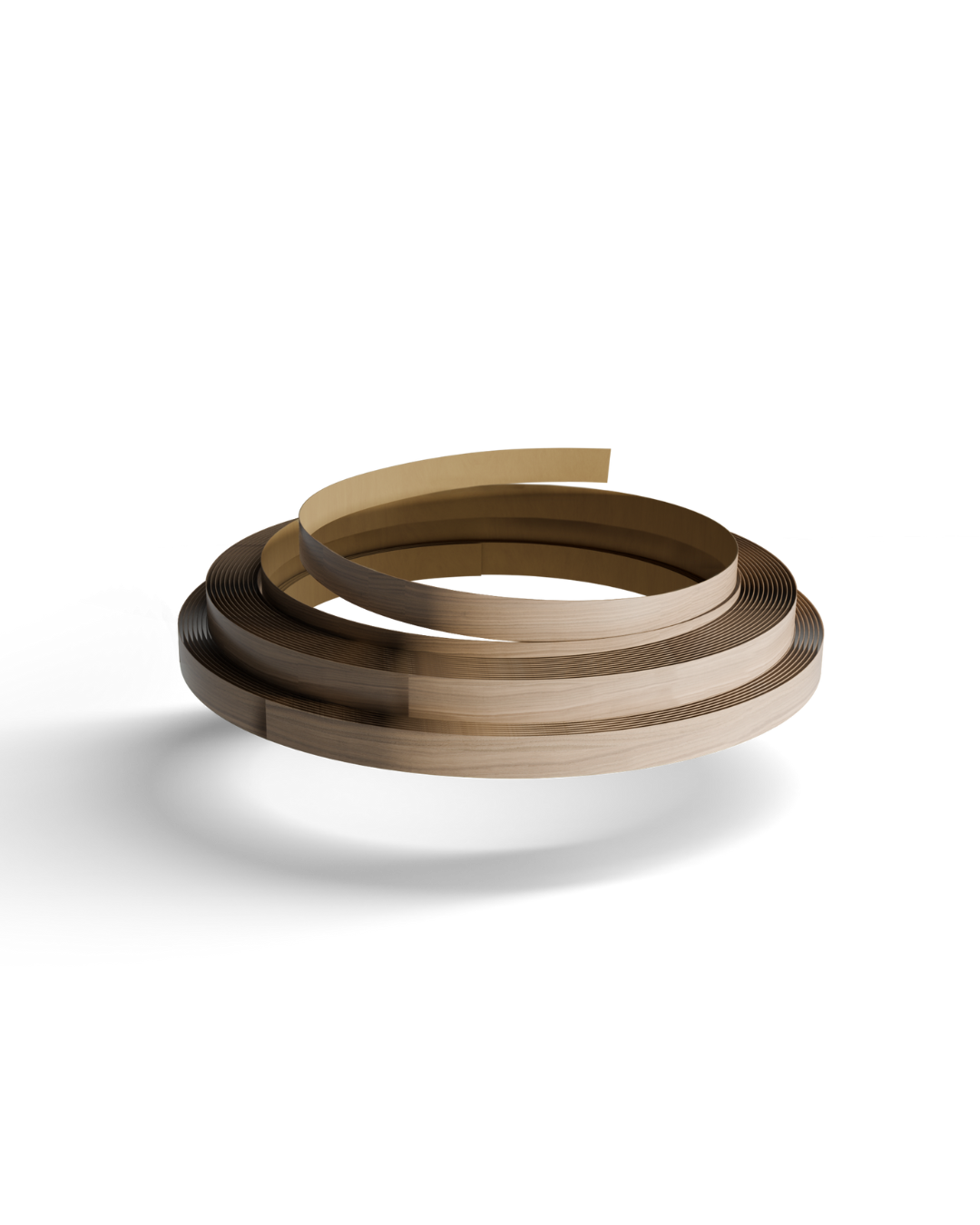

Nuxe edge banding is available in 2 widths, for all looks, assuring a refined finish to your interior.

- Veneer 24 mm x 100 m (15/16" x 328 ft)

- Veneer 48 mm x 100 m (1-7/8" x 328 ft)

Processing the edge banding:

Mechanically

By making use of hot melt bonding, compatible with the normal gluing tool as well as with the machines type BAZ (CNC machine putting the edge bandings on round shapes). The temperature of the hot melt: depending on the type of the hot melt (EVA, PA, APAO, PUR), is between 160°C and 230 °C.

Amount of glue: At the intersection of the edge banding and the panel you should see small glue dots to guarantee a good adhesion.

Manually

By making use of a two-component glue or contact glue (We refer to the instructions of the glue manufacturer). The humidity of the panel must be between 5% and 10% to guarantee a good adhesion.

The edges must be stored dry.

After removing the edge bandings from the packaging, they must be stored under a relative humidity of min. 40% and max. 60%.

Tolerances: width: ± 0.10 mm and thickness: ± 0.10 mm.

For the storage, handling & processing of Nuxe, check our downloads.

Nuxe is a natural product and is subject to discoloration by UV exposure. Check our downloads for warranty conditions.